Use Criteria

The Pulse Brand’s ‘Made with Pulses’ seal identifies the presence of pulse ingredients within a product formulation. Minimum inclusion levels (use criteria) have been established to determine eligibility. It is the responsibility of the User to ensure that the use of the ‘Made with Pulses’ seal is compliant with the laws and regulations in jurisdictions where the food in question will be marketed. Regulatory guidelines may also require or suggest quantitative or percent declarations.

To be eligible to use the ‘Made with Pulses’ seal on products, the food in question must meet both of the criteria:

| Use Criteria | |

| Criteria One: | Criteria Two: |

| The pulse ingredient(s), alone or in combination, must be within the first five (5) ingredients of the formulation by weight. | The pulse ingredient(s), alone or in combination, must be within 5 percent (5%) or more of the formulation by weight. |

Inability to meet BOTH of these criteria disqualifies the food from using the ‘Made with Pulses’ seal.

| How to determine which products qualify to use the pulse brand | |

| Step 1: | Use Eligible Pulse Ingredients, to confirm the pulse ingredient(s) is (are) eligible. |

| Step 2: | Calculate the percentage of eligible pulse ingredient(s), relative to other ingredients, to determine if the food is in accordance with the the use criteria above. |

| Step 3: | Review the laws and regulatory requirements of the jurisdiction in which food the will be sold to ensure the label is compliant with all applicable laws and regulations. |

Use Criteria Calculations

To calculate the amount of pulses in a food product, the weight of all ingredients within the formulation is required.

The proportion of pulse ingredients, relative to other ingredients, are based on the weights of ingredients before they are combined to make the food (see Example #1). However, there are exceptions and considerations where proportionate weights of ingredients may change relative to the weights at the time of mixing. Examples include, but are not limited to, added water or volatile ingredients lost during processing (see Example #2), the presence of concentrated food ingredients or products that require additional ingredients during preparation by the end user. Consult local regulatory guidelines to determine if calculative considerations are required for these, or other scenarios.

Note:

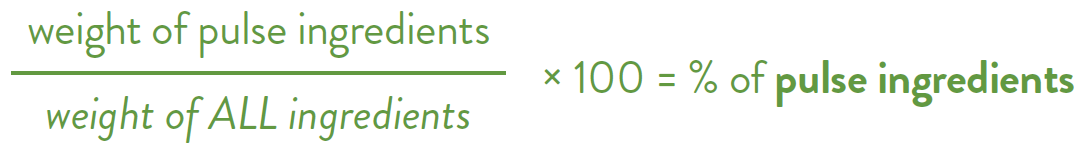

When the formulation contains multiple pulse ingredients, the numerator is the combined weight of all pulse ingredients.

Formula:

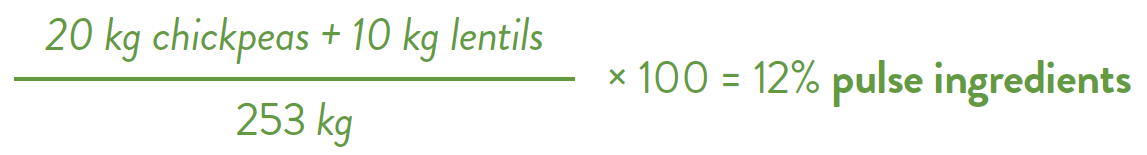

Example #1:

The following ingredients are mixed together to formulate a confectionery food product: 200 kg chocolate, 20 kg peanuts, 20 kg roasted chickpeas, 5 kg toasted rice, 5 kg caramel and 10 kg roasted lentils. Total weight of mixed ingredients: 253 kg

The proportion of pulses in the food:

In combination, the pulses (chickpeas and lentils) are the 2nd ingredient by weight and 12% of the formulation. This product qualifies for use of the ‘Made with Pulses’ seal.

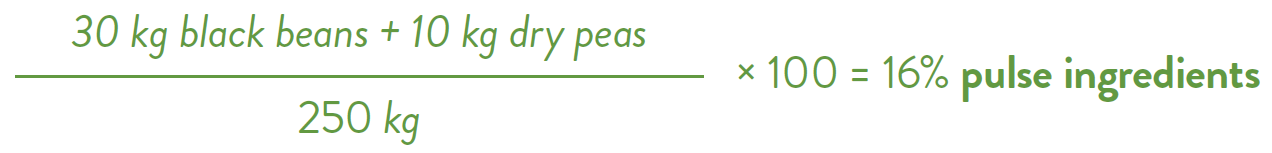

Example #2:

During the formulation mixing stage, the following ingredients are added together to make a soup: 100 kg water, 70 kg chicken broth, 30 kg black beans, 20 kg noodles, 20 kg chopped tomatoes, 10 kg dry peas, 10 kg onion, 10 kg celery, 10 kg potato. Total weight ingredients at mixing: 280 kg

Processing and cooking losses due to evaporation of liquid: 30 kg

Total weight of ingredients after processing and cooking: 250 kg

The proportion of pulses in the food:

In combination, the pulses (black beans and dry peas) are the 3rd ingredient by weight and 16% of the formulation. This product qualifies for the ‘Made with Pulses’ seal.